Wild American Shrimp Supplier

Contact

Lafitte Frozen Foods, Corp.Raymond Poon, or

Michael Chan

504-689-2041

5165 Caroline Street

Lafitte, LA 70067

info@lafittefrozenfoods.com

lafittefrozenfoods.com/

Quick Facts

Year founded: 1979# of employees in peak season: 50 (Violet plant), 50 (Lafitte plant)

# of family members working in the business: 4

Product type(s): Brown, white, peeled, peeled and deveined, headless, IQF, Block frozen

Capacity (pounds per day): Coming soon

Square footage of facilities: 60,000 (Violet plant), 40,000 (Lafitte plant)

Interesting fact about the business: Coming soon

Product brand names: Coming soon

Lafitte Frozen Foods Corporation is a family-owned operation that has gained a solid reputation in the shrimp industry as one of the largest domestic processors in the United States. The impeccable approach to providing customers with a quality product for the last 35 years is attributed to the company’s dedicated team, which is comprised of a unique blend of cultures, innovators, out-of-the-box thinkers, and hard workers.

The history of the company goes back to its founder, Paul Poon, 65, who emigrated to America from China with his wife in 1975 to give his family a better life. In this particular industry, nothing comes easy, but with a work ethic grounded in excellence and an unwavering hope to survive the waves of uncertainty, the American Dream is a possibility for anyone willing to do what’s necessary to make it happen.

Paul’s story is an impressive tale of tenacity from start to finish, but his humble and gracious demeanor would never allow him to boast about his success. That’s just not who he is. However, his sons, Raymond Poon, 39, and Jason Poon, 35, and nephew, Michael Chan, 41, who are all very active in the family business, are happy to honor their father and uncle with accolades.

“I’m very proud of our father,” says Jason, treasurer. “This is not something that was given to him. He earned every single bit of everything he has today on his own. His brain is always moving, and he makes things happen.”

Raymond, senior vice president, adds: “We are very proud of my dad. He’s been through a lot, and we need to continue to build the legacy. He built this from scratch, and we need to continue to move it forward.”

Michael says Paul didn’t have much formal education, but that never stopped him from pursuing a better life: “The day he touched ground in the U.S., he didn’t know a single word of English,” he says. “An opportunity was given to him, and he fully cherishes every moment of it.”

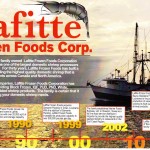

Lafitte Frozen Foods is based out of Lafitte, Louisiana, a historic fishing community located 20 miles south of New Orleans. When Paul started the company in 1979, there were only four peeling machines onsite to accommodate a hand-packed product. Now, the company has grown to 16 peeling machines and is comprised of three facilities: the Lafitte plant, where corporate offices also are housed; a plant in Violet, Louisiana, which is around 13 miles from New Orleans; and a value added plant that’s only three miles down the road from the Lafitte facility.

In 1999, Paul bought Samanie Packing in Dulac, Louisiana — a processing plant with history that dates back to 1941 — and in 2002, the companies merged under Lafitte Frozen Foods. This move increased production significantly, but in 2011, an opportunity opened to purchase an old shrimp cannery in Violet to replace the production in Dulac. In record time, the Lafitte team completed a six-month renovation, and by the 2012 shrimp season, the 60,000-square-foot-facility was up and running with cutting-edge technology that positioned the company as one of the leading processors in the U.S.

In order to focus on the new facility, the plant in Dulac was closed, and Paul moved some of his key employees to Violet. One of those team members was Robert “Bobby” Samanie III, vice president and overseer of the operation in Violet. Bobby, also known as “Captain Bob” by his peers in the industry, comes from a family with a rich seafood legacy himself. His great-grandfather started the Dulac plant, which was then operated by his grandfather and father, and then passed on to Bobby.

The shrimping life is all he’s ever known, and he jokes when he says, “Some people say I cut my teeth on peeling machine rollers!” Bobby is a wealth of knowledge about the Louisiana shrimp industry, and he takes great pride in his job at Lafitte. His detailed understanding of all the ins and outs of the machinery and various processes is impressive, and he beams when talking about how the renovations at the Violet plant made it a fully automated facility.

Understanding all the intricacies of how the equipment operates is crucial to an efficient system that produces a consistent product, and it takes people like Bobby to help streamline the effort with ease: “Knowing the science of the peeling machines is everything,” Bobby says. “You have to peel the shrimp, but you can over-peel them, and if you over-peel, you lose yield. The second most important part is the grader system because that has to be right on track also. We have two people counting and two people constantly adjusting the settings. It takes years to learn how to run a grader properly.”

Bobby also has played a significant role in helping to train Raymond about the processing business. Being the oldest son in the Poon family, he was always destined to take over the company one day. After Raymond earned his management degree, he moved to Dulac straight out of college to learn more about the industry, which he says helped him greatly.

“My dad sent me to Dulac to work for Bobby,” Raymond says. “I was 25-years-old and didn’t know much about running a shrimp business, but when I went to Bobby’s plant, he became a mentor for me. Working for him was like family. He taught me how to sell shrimp and how to work with customers.”

Like a proud dad, Bobby says, “Raymond picked up sales and blew right by me. I am so proud of his accomplishments. He’s done a great job.”

Jason also grew up in the industry, but his path led him on a different route to explore some business opportunities in Texas after he graduated from college with an economics degree. After doing financial planning for a year, he decided to come back and help the family business as manager of Lafitte’s sister business, Marine Foods Express, a Houston-based company established in 2002 that specializes as a full line food service distributor.

“We have more than 2,000 items that we import from around the world and carry domestically,” Jason says. “We try to carry as much as we can to service all the restaurants’ needs in the Texas and Louisiana region, as well as wholesalers and distributors across the country.”

Michael joined Lafitte in 2000, and because he didn’t come from a seafood background, he had to start from the beginning, but says he wouldn’t have wanted it any other way: “When I started in the company, I pretty much started from the ground up,” he says. “What my cousins did when they were 13-years-old, I did when I was 27-years-old, but I’m glad I started that way. The only way you really learn this industry is by being hands on, and the only reason I have learned this industry is because of the opportunity Paul gave me.”

The leadership team in place has guided Lafitte Frozen Foods to accomplish great things like embracing automation as much as possible without ever sacrificing the quality of their brown and white shrimp, which are available peeled, peeled and deveined, and headless. Both plants are laid out with the best of the best in equipment and technology, especially the IQF custom packing system that can process 3,500 pounds per hour in 1-pound and 5-pound retail bags, as well as pack two different sizes at the same time, with the option of packing two different brands for retail customers.

If customers prefer block frozen, a 580-horsepower compressor operates a spiral freezing system that freezes a 5-pound box in only four hours. Traditionally, this used to take 16 hours before the advanced method was implemented to speed up the process. Lafitte also has three blast freezers onsite that allow a “redundant system” to be in place. In the event one goes down, all processes keep moving forward with no interruption.

Whether retail, distributors, food service, military, institutional, grocery stores or wholesalers, Lafitte caters to all types of customers’ needs in markets where their five different brands of wild caught domestic shrimp are prevalent: in the south, Midwest, East Coast, and Canadian markets. Between both plants, up to 200,000 pounds of shrimp are processed per day.

“Our company’s strengths are integrity, quality and pride,” Jason says. “We have resources in both of our facilities in Lafitte and Violet that let us cater to our customers’ needs. If you want it, we can do it.”

In 2010, the company expanded by adding Bayou Barataria Foods, LLC — a 20,000-square-foot value added facility located only three miles down the road from the Lafitte plant, which allows for the freshest seafood to be transformed into a tasty line of specialty products made strictly for the food service industry and various retail applications. Marine Foods Express plays a large role in distributing these products to customers.

Breaded products (fish fillets, shrimp nuggets, shrimp burgers, popcorn shrimp and shrimp balls) are available, as well as the company’s highly demanded culinary delights such as Shrimp and Artichoke Poppers, Shrimp and Pepperoncini Poppers, Creole Crawfish Florentine Croquettes, Crawfish Crab Boil Bombs, and Crawfish, Spinach and Artichoke Dippers.

To offer an extensive line of high-end appetizers and specialty food items nationwide means everything must follow state, FDA, HAACP and USDC regulations within a top-of-the-line facility designed with state-of-the-art equipment. Bayou Barataria is comprised of a fully integrated system that can produce up to 20,000 pounds a day, per value added item, but before products enter the marketplace, they must pass rigorous quality assurance testing.

One unique piece of machinery that is at the epicenter of bagging is the “combination automated bucket scale” with 14 hoppers for precise measurement and bagging of all products ranging from 12-ounce up to 10-pound bags. Customers also have the option of Bayou Barataria labeling or private labeling.

The credit behind the innovative vision and consistent development of Lafitte Frozen Foods belongs to Paul: “This is all Paul’s design; he drew the blueprint,” Bobby says. “He’s the visionary, and we just try to make it come to life for him. Paul is living the American Dream, and he has earned every bit of it. I’m so proud to work with him; he’s the heart of the company.”